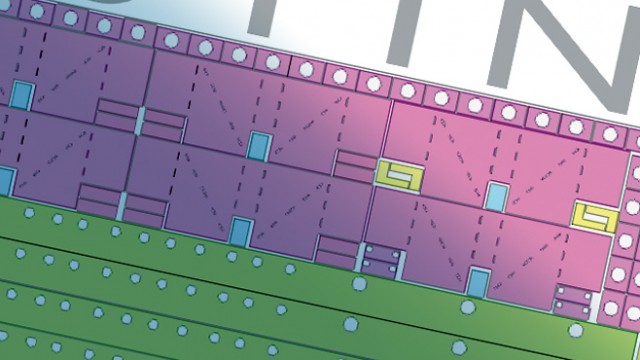

The quality of Tecnocarp’s products is also based on an in-house technical department able to read, analyse and develop the design in the most efficient and suitable way in relation to the client’s needs. The work is carried out with 3D CAD systems, from which the relative specifications, details and work sheet are obtained for each single piece. The cutting plans are decided with a specific CAD/CAM software to optimize sheet cutting (nesting) in order to reduce scraps to the minimum and obtain an initial saving on the use of raw material.

Client support

Thanks to many years of experience in the industrial metalwork field, Tecnocarp’s technical department is able to evaluate, during the analysis phase, the feasibility of the pieces to be produced and propose possible alternative solutions. This implies the resolution of potential problems, thus optimizing the execution times with a consequent reduction in costs.

Planning

Tecnocarp plans the production with computerized systems and thanks to the constant monitoring of the same production phase, it is able to guarantee punctual deliveries.

Nesting

Tecnocarp uses a steel sheets warehouse with a constant stock of 5,000 quintals, that supplies the production cycle, thus ensuring prompt execution of orders.

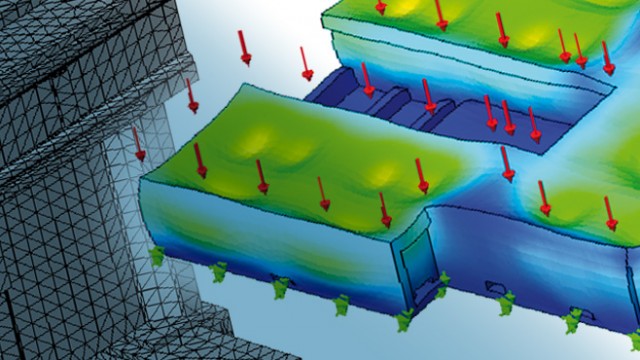

DESIGN

Furthermore, thanks to the partnership established a few years ago with a prestigious technical design office, which can boast many years of experience in the design of highly technological machines, Tecnocarp is able to offer a finished product, possibly complete with structural calculations, FEM analysis and drawings developed with 2D-3D CAD systems.