CUTTING DEPARTMENT

Not a simple product but an actual challenge which is accepted and won daily, to complete the most demanding orders successfully.

Tecnocarp’s cutting department is able to offer plasma cuts with 360° rotating head that can bevel during the cutting phase, thus reducing the work times and improving the execution quality. It can also count on flame cutting, shearing machines, saws of various sizes and bevelling and bending machines: equipment that makes it possible to process pieces of any different size or type.

BENDING DEPARTMENT

Tecnocarp is equipped with a bending department able to work sheets and other materials, using high quality and precision equipment.

ASSEMBLY DEPARTMENT

Tecnocarp relies on solid foundations, know-how and enthusiasm to win the quality challenge every day.

Thanks to the use of next-generation equipment and continuous monitoring of the work phases, the assembly department is able to produce single pieces and medium/large batches.

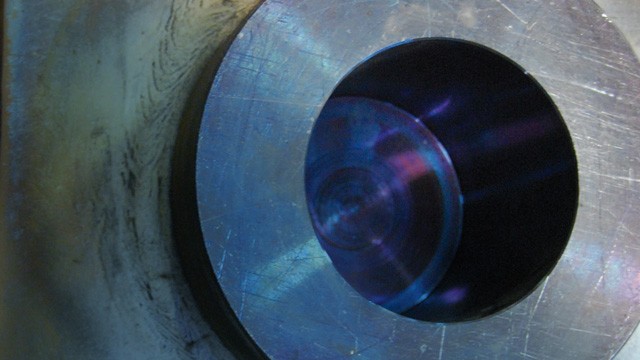

WELDING DEPARTMENT

Tecnocarp’s welding department has always represented the craftsmanlike core of the company.

The welding works performed by Tecnocarp stand out in terms of the cleanness and refinement of the execution. The welding processes and operators must be qualified according to EN ISO 15614-1:2005 and ASME IX standards.

In addition, Tecnocarp has experience in welding guides in C45 quality with pre-heating and has 500 A digital Mig/Mag machines.

STRAIGHTENING

Straightening is carried out by means of flame or press and using outstanding ability and experience. In case straightening is done by flame, the piece is heated in a specific point and for a suitable time, in order to obtain a good result in terms of flatness and avoid problems during processing with machine tools.

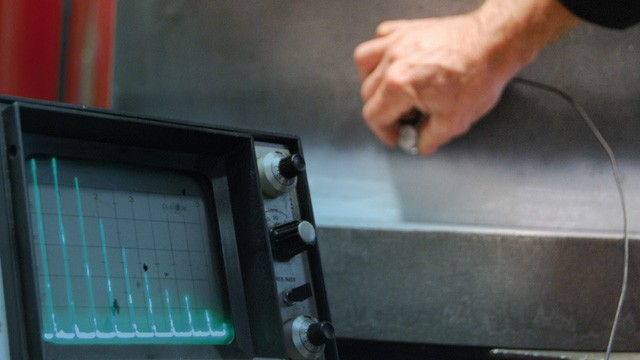

TESTING DEPARTMENT

In the testing department, in addition to the usual dimensional tests, Tecnocarp also performs technical, non destructive tests upon request, such as ultra-sounds, magnetoscopic tests and penetrating fluids, always with the aid of internal staff, qualified according to the UNI EN 473 – ISO 9712 standard.